General FAQs

What is Kebony?

Kebony is a highly durable, sustainable wood with the aesthetics and performance of the best tropical hardwood. It requires minimal maintenance with low life cycle costs.

What is the difference between Kebony and heat-treated woods?

Kebony technology is a combination of the infusion of a bio-based liquid and exposure to heat in the excess of 100°C, which permanently thickens up the cell wall of the wood. Heat-treated timber processes are purely high temperature treatments (170°C – 215°C), which does not alter the cell structure of the timber, but stiffens and makes the cell walls more brittle.

How is Kebony disposed of at the end of its life?

Kebony wood can be handled as ordinary wood. It can be recycled, repurposed, or burnt.

What applications can Kebony be used in?

Kebony can be used both indoors and outdoors in applications which include decking, cladding, flooring, roofing, windows, doors, furniture and design objects

Is Kebony easy to work with?

Kebony is much easier to work with than tropical hardwoods. Carbide tools should still be used but will last much longer.

Does Kebony come with a warranty?

Kebony offers up to a 35 year warranty against rot, this warranty varies based on product and use, please review prior to making a claim. A detailed version of the warranty can be viewed here.

Who sells Kebony?

See the Where to Buy section on our website or submit an online quote request.

How do I request samples of Kebony?

You can request a free sample online, send your inquiry to [email protected] or contact your nearest retailer.

How do I place an order?

You can submit an online quote request, send your purchase order to [email protected] or contact your nearest retailer.

Is Kebony dimensionally stable?

The Kebony process substantially improves the wood’s dimensional stability, typically by 50% compared to the original wood species. For example, Kebony Clear will swell tangentially by only 4% – better than almost all other woods.

What are the mechanical properties of Kebony?

The bending strength of Kebony is roughly unchanged from the parent wood, while the stiffness is improved by 10-20%. The hardness is typically improved by 30-50% over the parent wood. Complete specifications can be found in the relevant product information sheet.

What are the physical properties of Kebony?

Kebony is a natural product. Our process alters the wood fibers’ ability to hold moisture as a result of cell modification. Kebony has lower moisture content than untreated wood when it is in equilibrium with its surrounding climate. This effect is caused by the formation of the polymer inside the wood fibers. The process also reduces the shrinking and swelling of Kebony compared to the parent wood by 50%. The dimensional stability at moisture variations is therefore vastly improved.

Is Kebony maintenance free?

Kebony wood does not require any special maintenance beyond normal cleaning.

Is Kebony FSC® certified?

Both Kebony Clear and Character are FSC Mix 70%.

How does Kebony machine?

Kebony is about as hard as domestic hard Maple. Consequently, Kebony should be machined at slower feed rates using carbide-tipped knives.

What is Kebony’s carbon footprint compared to other tropical hardwoods?

Kebony has a substantially lower carbon footprint than most tropical hardwoods.

Is Kebony available in different colors?

Kebony wood is delivered in a dark brown color as a result of the Kebony technology. The shade of brown does vary slightly depending on the wood species. If left exposed to the elements, all Kebony woods will develop a silver patina over time.

Technical FAQs

Can Kebony be ripped and/or crosscut?

Kebony Clear can be both ripped and crosscut. We recommend using high quality carbide blades that are suitable for tropical hardwoods.

Kebony Character can only be crosscut and should not be ripped as it will expose untreated heartwood. We recommend using high quality carbide blades that are suitable for tropical hardwoods.

Do I need to seal the wood after cutting and/or ripping?

End-sealing is not necessary for Kebony Clear and should NOT be used as the sealant can interact with any finish that may be applied to the top surface. Furthermore, the use of end-sealers may result in uneven weathering of Kebony.

Kebony Character crosscuts must be sealed using an anti-parasite/fungal agent. Follow the manufacturer’s instructions.

What is the Solar Reflectance Index (SRI) of Kebony Clear?

The SRI values under Low, Medium, and High intensity are respectively, 49.1, 49.3, and 49.4

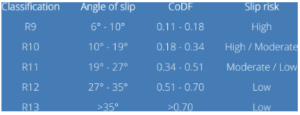

What is the Slip Resistance of Kebony?

There is no one recognized standard test for slip resistance. Kebony has performed several different tests in an effort to illustrate performance in different conditions.

DIN 51097

DIN 51097 ramp testing is a pedestrian slip test method utilizing soapy water and bare feet.

The outcome of this test was a rating of Group A.

DIN 51130

DIN 51130 ramp testing is a pedestrian slip test method utilizing motor oil and cleated safety boots.

The outcome of this test was an R11.

Fastener Location

All fasteners require pre-drilling. Kebony Clear requires that fasteners be located at least 1” from any edge. Kebony Character requires that fasteners be located at least ⅝” from any edge.

What fasteners should I use with Kebony products?

We recommend using 304 or 316 stainless steel screws on Kebony products. The specific grade should be selected by the contractor based on site specifics. The International Code Council Evaluation Service Report states that #8 screws should be used for decking applications. Do not nail.

Fasteners are provided when Grad™ for Kebony system, Step-Clip for Kebony, the Fastenator Hidden Fastener System or Pro Plug® System for Kebony Wood are selected.

What grade of stainless steel is used for the Step-Clip nails?

316 Stainless Steel

What grade of stainless steel is used for the Fastenator screws?

316 Stainless Steel

What grade of stainless steel is used for the screws provided with the Pro Plug® System for Kebony Wood?

316 Stainless Steel

What is the grade of aluminum used for the Passive Rainscreen System Clips?

EN AW 6063-T66

How much does Kebony Clear decking weigh?

5/4 x 6 decking weighs approximately 1.55 lb/LF.

2 x 6 decking weighs approximately 3 lb/LF.

The density of Kebony Clear is approximately 41.8 lb/ft3 or 670 kg/m3.

How hard is Kebony Clear decking?

Kebony Clear’s Janka hardness is 1619 lbf.

What is covered under warranty?

You can see the complete warranty here.

How do I clean my Kebony?

Water and a brush with only garden hose pressure. Do not use a pressure washer.

What is the minimum allowable ground clearance for Kebony Clear decking?

The minimum required clearance is 1.5” except when over exposed ground. In such cases, the clearance should be determined by the installer based on site specifics.

I’m seeing some discoloration/staining on my Kebony. What’s going on?

Click-in Cladding FAQs

Where are the Mini Rails manufactured?

France

Does water get trapped behind the Mini Rail when it’s placed horizontally?

We won’t need to worry about trapped water for several reasons: (1) the aluminum rail and plastic clips don’t absorb water like wood furring strips, (2) the board is not in contact with the rail – only the clip – so water and air can still pass between the board and rail, (3) the rail itself is not thick enough to trap enough water to cause an issue, and (4) the air gap will make sure that any water that is trapped will dry fast.

What’s the size of the air gap between the board and wall?

12mm or 0.47”

What types of fasteners are required?

You can use 316 Stainless Steel Ring-shank nails for a pneumatic nail gun (best option) or self-tapping 316 stainless steel screws designed for use with aluminum.

What grade of aluminum is used for the rails?

6060-T66.

What are the clips made of?

POM (Polyoxymethylene). Typical applications for POM include high-performance engineering components like small gear wheels, ski bindings, fasteners, gun parts, lock systems, or automotive parts. It has an operating temperature range of -40 °F to 160 °F.

Are any of the materials recyclable?

Yes! Both the POM clips and the aluminum rails are recyclable.

How long has this product been on the market?

Although the Grad Mini Rail is new to the US market, Kebony and Grad Concepts have been used together for more than ten years in Europe.

What is the coverage for a box of mini rails?

Can the Grad Mini Rail be used for decking?

No, the Mini Rail currently designed for cladding applications only. However, Grad Concepts does have rail and clip system solutions for decking. For more info, you can contact Grad Concepts USA: Go to the Grad website.

What is the fire rating for multi-family residential?

The required fire rating is determined by the construction type and the local building codes. It’s the responsibility of the architect to determine this. Our basic fire rating is established by ASTM E84 as Class B. That typically means the use is limited to structures approximately 40’ high.

What's the wind load rating?

We are currently testing the wind load rating for use in hurricane zones or other areas with strict WLR requirements. If you have a specific test requirement based on your city or county, please let us know at: Email Us.

How well will the aluminum last in a corrosive saltwater environment?

Specific testing hasn’t been done on this grade of aluminum, but the rail has a painted coating on the exposed face and is very well protected from the elements by the wood cladding.

The clip broke off the rail, what do I do?

The clips are designed to snap unto the rail and not move. If one breaks off and if still usable, you can simply snap it back in place. If it’s not usable, you use a riser clip in its place. Make sure you place the clip is the exact same location so it will click into the board.

How close can we place a Mini Rail to a corner?

The Mini Rail should to be 4″ or less from the corner. We don’t recommend extending the end of the board further than 4″ from the rail.

What's the gap spacing between the cladding and the trim?

Kebony swells very little lengthwise, but it can swell up to 4% in width. So if the trim is running parallel with the board, allow for swelling in the gap size. We recommend using a similar gap size as your Mini Rail (roughly a 1/4″ or an 1/8″ depending in the rail) to account for swelling and keep the overall aesthetic of the project.

What’s the distance from the front of the board to the wall?

33mm or 1.30”